Operations

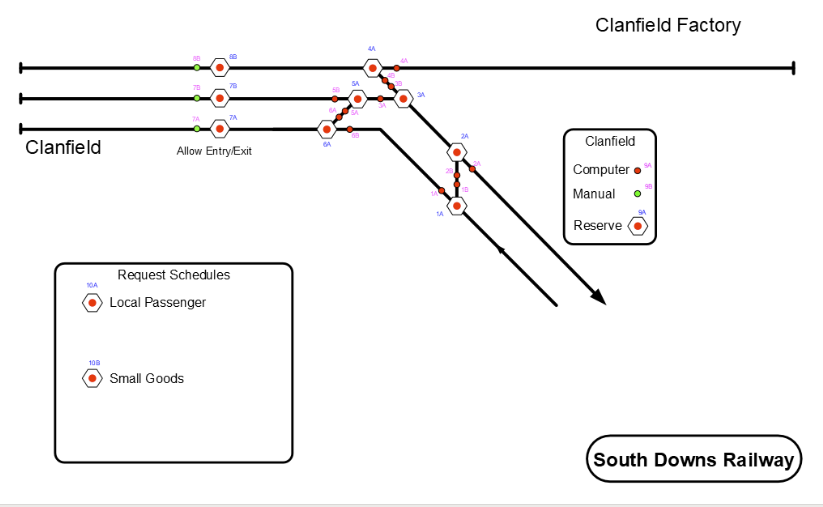

A smaller goods train will eventually be added. It will live in a hidden siding under Portsmouth, and visit Portsmouth container yard and Clanfield factory periodically. Manual operations will be needed at both. Clanfield factory is interesting, because the factory was added as an afterthought. Traincontroller can send the goods train to the rear platform, but getting the locomotive released isn't obvious. There's an uncoupling magnet in place at the platform end, but no others.

The selected approach is for the main line loco to push the wagons into the factory, then for a captive shunter to return them. An operation that works is as follows:

- A captive shunting engine lives at the end of the factory siding.

- A Traincontroller schedule delivers the goods train to Clanfield platform 1, as normal. The schedule does not separate the engine and goods wagons.

- Reserve the station for manual control.

- Change the point to allow access to the siding.

- The engine will have stopped over an uncoupling magnet. Using a throttle, make sure the engine and wagons are uncoupled; then push the wagons into the siding using "delayed uncoupling" (ie the couplings don't reconnect when over a magnet). TC thinks they are still coupled.

- TC automatically performs a "separate" operation when the factory block becomes occupied.

- The engine can now reverse, re-enter the station then move to a vacant spot on platforms 2 or 3.

- Release the station from manual control.

When it is time for the train to depart the reverse process is:

- Reserve the station for manual control.

- Use a throttle to select the shunter.

- Manoeuvre the shunter until it touches the wagons, then stop. TC detects it entering the block and performs a "join by train tracking". The shunter doesn't have a compatible coupling, and isn't physically connected.

- Use the shunter to push the wagons to the platform.

- A flagman detects the platform 1 block become occupied while the shunter's home block is unoccupied, and initiates a "separate" operation.

- Return the shunter to its home at the end of the siding.

- Drive the locomotive onto the end of the wagons and reconnect. TC performs a "join by train tracking" when the loco stops in the block.

- Release the station from manual control and select the goods train schedule.

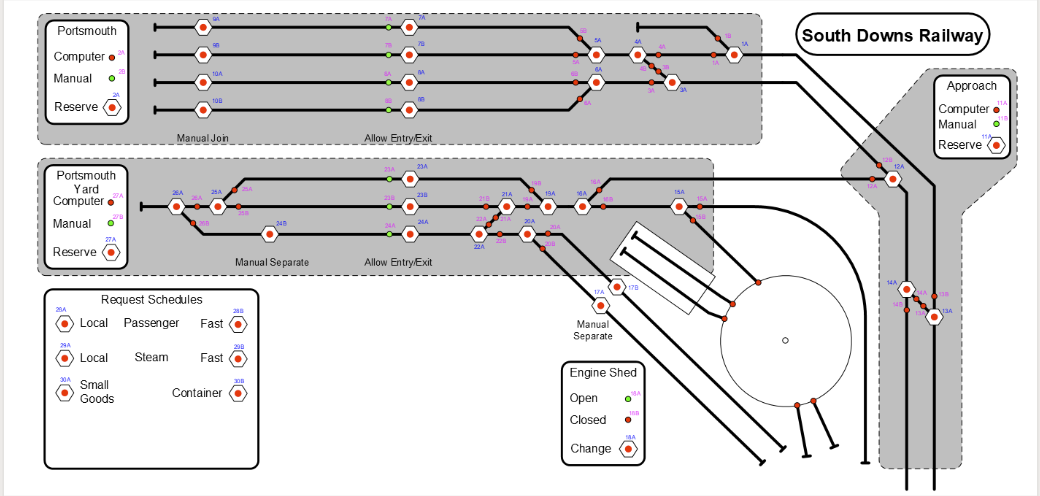

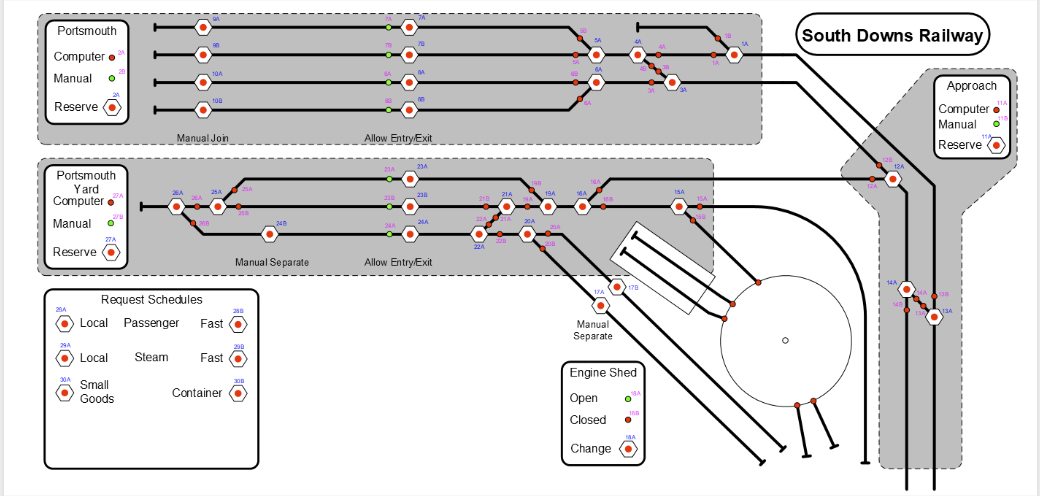

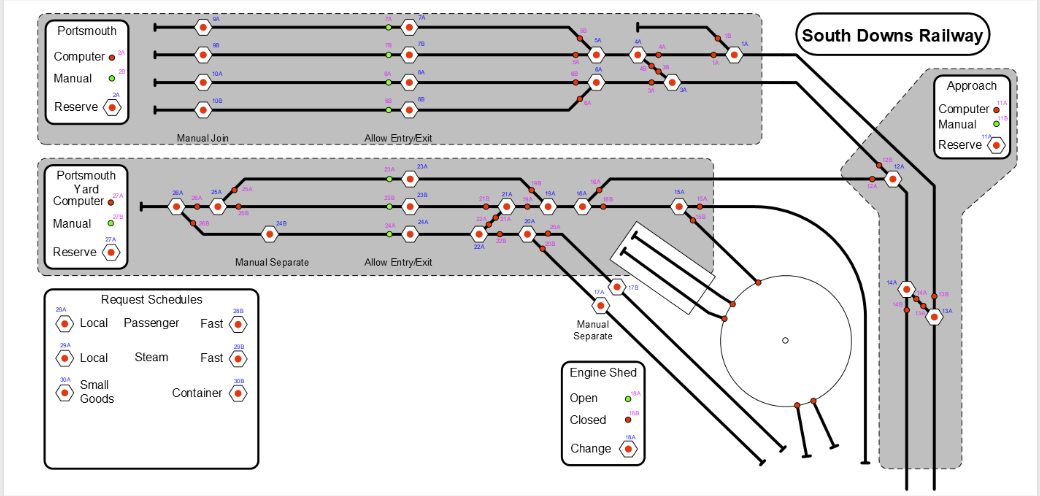

The container train is a set of 7 bogie trucks carrying ISO containers, hauled by a main line goods locomotive. Its "home" is Portsmouth container depot, and will follow a similar cycle to the oil train: move to a hidden siding; run round the layout several times; then return. The operator will need to move the locomotive to the other end in the usual way. The local control panel is a key part of this process.

- Press "Reserve" on Portsmouth Yard so it reports "manual". This will prevent Traincontroller driving trains into the track you are using.

- Use a throttle to select the locomotive that has just arrived.

- Check the containers have uncoupled. If not, shunt back over the magnets then pull forward again.

- Use the control panel to set the points to allow the loco to move to the track end.

- Drive the loco to the track end.

- Use the control panel to select a track running around the containers.

- Start moving the loco past the containers.

- Use the control panel to select a path onto the exit road.

- Drive the loco onto the exit road & stop.

- Use the control panel to select a path to the front of the contained wagons.

- Drive the loco onto the container wagons, couple and stop.

- Select the loco direction to be ready to leave the depot.

- Deselect the loco from the throttle.

- Release the container yard back to automatic control by pressing "Reserve" again.

- If needed, press the button on the track holding the container train to make sure "allow entry/exit" is lit.

- Initiate a new schedule by pressing "container" in the "Request Schedules" section.

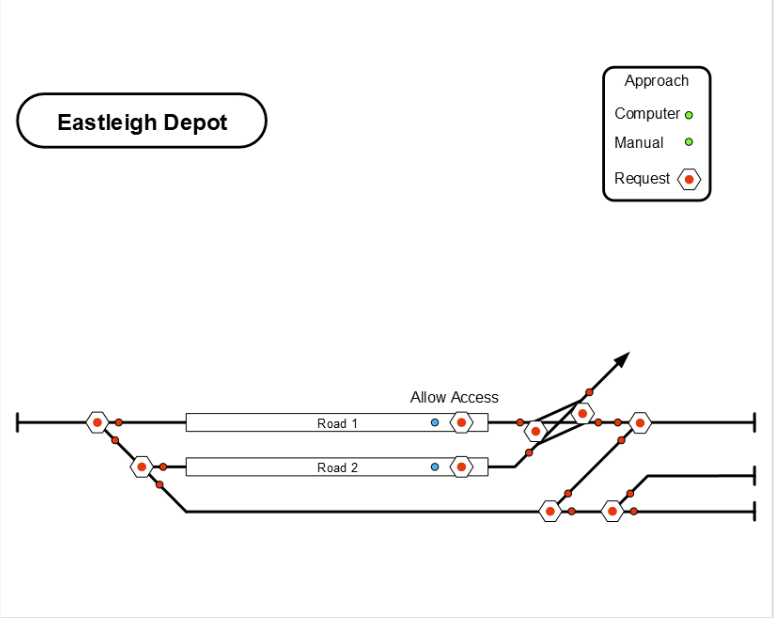

The oil train is a set of 8 bogie oil tankers hauled by a main line diesel locomotive. It begins its journey at the Eastleigh oil depot; the operator sends it on its way by pressing a "schedule request" button on the DTM30 panel. That button initiates a schedule sequence, currently containing three schedules.

The first schedule takes it to a hidden siding under Eastleigh depot. There it waits until the second schedule runs. That is programmed to do 5 "laps" of the railway with a pause at the same location for a few minutes. The result is the train is seen "out and about" a few times. after the 5th lap, the final schedule runs to bring the loco back to Eastleigh. The locomotive uncouples, because there are magnets positioned under the track at the correct location. The schedule has an operation at its end which splits the locomotive from the oil tankers.

Once at Eastleigh, the operator has to get the train ready to depart again. They need to drive the loco manually to the head of the depot, using the DTM30 to change points as they go. An interlock with Traincontroller prevents further automatic train movements until this has been completed. They drive the train around the "run round" loop and couple it back onto the other end. Finally they press the button to initiate the new schedule, and the cycle repeats.

The operator steps, when a train arrives, are:

- Press the "allow access" buttons on the tracks as required to get the track with the newly arrived train unlit.

- Press "request" to get manual control for the depot; the green "manual" LED should light.

- Use the point pushbuttons to enable access for the loco to the head end of the depot.

- Select the incoming loco with a throttle and drive it to the head end.

- Select the points to access the "runaround" track closest to you.

- Start driving the loco onto the runaround track.

- Select the points at the other end to access the end track in the depot and drive the loco to there.

- Select the points to access the track with the tankers ready to leave.

- Drive the train to the tankers and couple up.

- Deselect the loco on the throttle.

- Press "request" to give the depot back to automatic control.

- Press the "allow access" to light the LED for the track ready to depart.

- Press the schedule request button.

A smaller oil train may eventually be added. This would take oil to Clanfield factory, and to Portsmouth. That would need some carefully thought out manual operations.

There is a GWR preservation group at Portsmouth station with a few of locos and small carriage sidings (the latter appear big enough for 4 carriages, allowing for uncoupling magnets). A large steam loco would take an excursion train around the railway and back to Portsmouth. A pannier tank + 2 carriages could go to the terminus platform at Petersfield then on to Clanfield and back to Portsmouth.

We're using the "train sets" feature of Traincontroller to manage the loco and carriages as separate entities. We need to join them and separate them at particular times. Generally we can do "join by train tracking" and have "separate" initiated at the end of automatic schedules; but sometimes explicit commands are needed. The sequence of events to start and end an excursion are as follows. You will need to use the control panel.

A human operator needs to prepare the loco to and from the passenger area. To prepare for a steam excursion:

- Use the DTM30 panel to reserve the Portsmouth yard area for manual train movements by pressing "Reserve"

- This will give you manual control of points, and prevent any trains being driven into the area under automatic control.

- Drive a steam loco from the engine shed then via the turntable to the front road in the goods area. It will need to leave the turntable facing backwards.

- Drive the loco into a carriage siding and couple to the coaches. (Train controller will automatically "join" the loco to the carriages).

- Reverse the loco and carriages to the end of the goods area front track, and uncouple on the magnet.

- Press the "manual separate" button the the DTM30 panel (this will send a sensor message to TC; a contact indicator will activate a button to do the "separate" to the train in the block).

- Drive the loco around the carriages to the other (front) end, and couple on. TC will do a "join" automatically when the loco stops moving in the same block as the carriages.

- Use the DTM30 panel to reserve the Portsmouth station and approach areas of track by pressing two "Reserve" buttons.

- Drive the loco and carriages out onto the approach road, getting completely off the Portsmouth "flap".

- Reverse the train onto the station platform.

- Press all 3 "reserve" buttons, releasing to automatic control

- Press the "allow entry/exit" button for the platform so the track is lit green.

- You can now initiate a steam schedule by pressing the fast steam schedule button.

- Now you can drive your excursion train - observe and stop at all signals!

To conclude a steam excursion:

- On arrival, TC has "separated" the loco from carriages and the couplings will be over an uncoupling magnet.

- Press "allow entry/exit" for the platform so the track LED is unlit.

- Reserve the station area, yard and approach areas by pressing their Reserve buttons.

- Press the "manual join" button for the platform.

- Reverse the train from the platform to the approach road, making sure the couplings re-couple.

- Drive forwards into the goods area front track, stopping at the mid point.

- Unreserve the station and approach areas by pressing their "Reserve" buttons. This releases them for automatic control.

- Reverse the train into a carriage siding, and uncouple over a magnet.

- Press the "manual separate" button to tell TC to separate the carriages & loco.

- Reverse the loco out

- Drive the loco onto the turntable then into the engine shed.

- Press the Portsmouth yard "reserve" button to release it back to automatic control.

The Pannier tank + autocoach will be quite easy - it's not direction sensitive, so can just be kept as a single unit. It runs the "slow steam" schedule.

The more traditional form of passenger train: a locomotive hauling a set of carriages. These present a challenge when they reach a terminus, because the locomotive needs to be replaced at the new "head" end of the train.

Our approach has the train driven from start to destination automatically. Once it arrives, it uncouples: there are magnets under the track at the correct locations. The schedule driving the train has a "split" operation at the end of the sequence to split the locomotive from the carriages.

A human train driver is then needed. They will bring a new locomotive from an engine shed or "spur" and couple it to the departure end of the train. A DTM30 control panel gives them control over the trackwork; an "interlock" allows them to prevent traincontroller from driving through the same track while it's happening. Because the platform blocks have a sensor at each end AND a sensor covering the middle, Traincontroller can detect the new locomotive arriving in the block and automatically couple it. Because we've been careful with sensor positions, it can use train tracking to "know" which locomotive is where.

The sequence required is:

- Press the "allow entry/exit" button for the newly arrived train so its track LED is unlit.

- Reserve the station area for manual control by pressing Portsmouth "Reserve". The "manual" LED will light. You will now have manual control of the points in the station area, and no trains will be driven in automatically.

- Select the loco on the spur using a throttle.

- Using the panel, select the points appropriately and drive the loco out from the spur onto the carriages, and couple to them.

- Press the "allow entry/exit" button for the newly arrived train so its track LED is lit.

- Release the station area to automatic control by pressing Portsmouth "Reserve". The "computer" LED will light

Once the train has departed, the human operator then needs to move the "old" locomotive to the engine shed or spur. Again, this is done manually. Traincontroller tracks it, so it knows which locomotive is in which spur or engine shed.

- Press the "allow entry/exit" button for the newly arrived train so its track LED is unlit.

- Reserve the station area for manual control by pressing Portsmouth "Reserve". The "manual" LED will light. You will now have manual control of the points in the station area, and no trains will be driven in automatically.

- Select the loco on the platform using a throttle.

- Using the panel, select the points appropriately and drive the loco out from the station and onto the spur.

- Press the "allow entry/exit" button for the vacated platform so its track LED is lit.

- Release the station area to automatic control by pressing Portsmouth "Reserve". The "computer" LED will light.