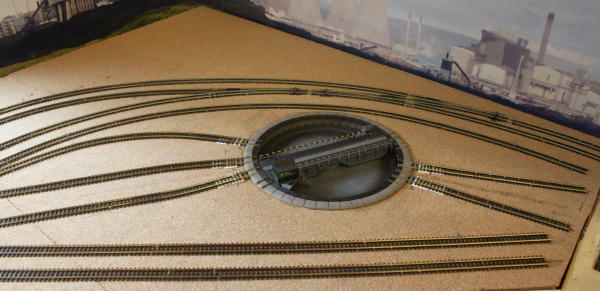

At last, the final pieces of track have been laid! All of the points feeding the turntable/engine shed area were laid before Christmas 2015, but the turntable itself still needed to go in before the tracks around it could be added.

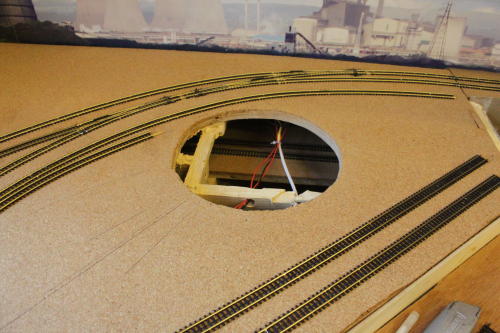

We have a Fleischmann 9152C turntable. This needs to be sunk into the baseboard, to a depth of around 8mm deeper than the plywood and cork. By chance, there were two sets fo supporting timbers under the turntable that have had to be cut away. Most of the plywood cuts were simple using a jigsaw; the bits above the softwood supports, and cutting the supports themselves, was done with an "oscillating saw" tool whose blade vibrates but doesn't rotate. The trick is to not press hard - doing so stops the vibrating action. The softwood in particular was really easy to cut that way.

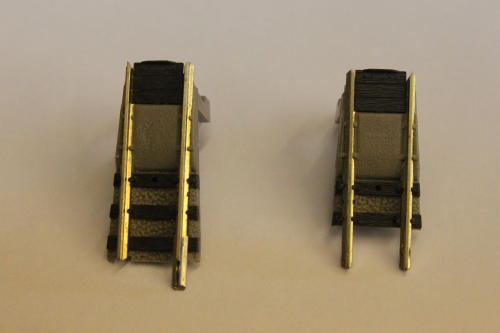

Mounting the turntable itself is easy: impact adhesive holds it into place. Joining the tracks wasn't so simple. It's well documented that neither Peco nor Fleischmann fishplates inter-mate with each other. The reason is that the Fleischmann track has a "flat bottom" profile with an very wide flat base, and the Peco code 55 track has a very bulbous centre section. As usual, after you've completed the job you discover the right solution...

Initially I set about using the Peco nylon fishplates to join the tracks; those stretched onto the Fleischmann track OK. However they also dislodged easily while trying to mate the Peco track onto them - not good with a clock ticking for the Evo-Stik glue to set.

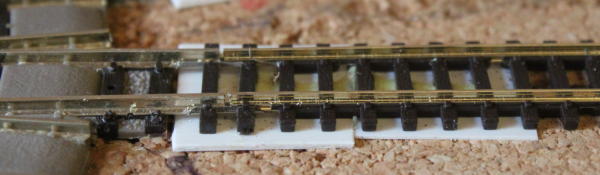

The solution came to me at the end: use a Dremel tool plus grinding stone to grind a little off each side of the Fleischmann track flat bottom. I'd removed about 5mm of plastic base from the Fleischmann rail joiners to give access for fishplates. (See the "before" and "after" picture below). You can then fit a Peco fishplate with a bit of pressure applied. The rails join at almost identical top positions, but the peco sleepers are approx 1mm above the baseboard.

The Peco track was laid onto a 1mm plastic "spacer" then a 0.5mm spacer to step down the height above the baseboard. As usual the track was glued down, and seems to be stable.

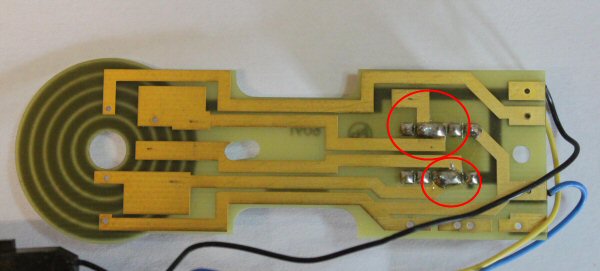

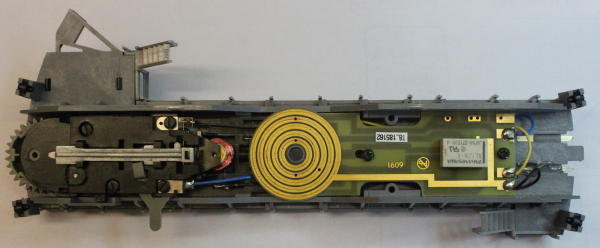

Finally I've modified the bridge to remove the spring contacts from the bridge track to the exit rails. Each exit rail has its power fed directly; those contacts would only cause shorts as the turntable moved. I also bypassed the relay that isolates a short length of track at each end of the turntable (I used two solder bridges between relay pins marked on the photographs)

The turntable is powered and controlled by a CML Electronics TXC1 controller, mounted under the baseboard. It indexes automatically to the next track position and skips unoccupied tracks. It's set to use DCC base address 401, and address 451 for computer control.

The remote knob and display have been integrated into a DTM30 control panel.