In various places, rails need to be isolated. This can be for several reasons:

- The two tracks from the point "frog" need isolation to the next track;

- Where the different power zones join, both rails need to be isolated;

- between different block detector zones, one rail needs to be isolated.

The simplest way to isolate is to use a nylon insulating "fishplate" when laying the track. We've used those on point frogs. But for the others, the positions can sometimes only be finaised after initial track laying.

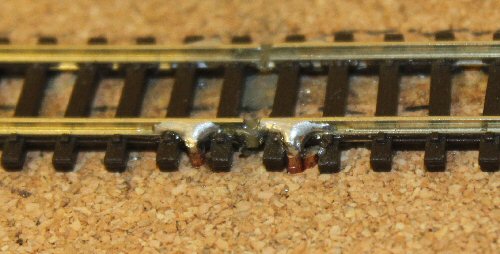

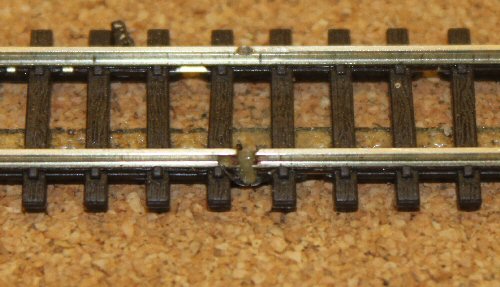

The approach we have used is to cut the rail using a dremel cutting disc, then isolate with araldite. This latter step ensures that the gaps can't close together later (e.g. because of other track laying operations, or thermal expansion). Simply insert a blob of epoxy, and let it set; then cut down with a sharp knife until it matches the rail profile.

Track cuts on bends are a bigger challenge. the problem is, when the rails are cut the tracks will tend to straighten out leaving to a step in angle for the train. The solution I used was to drive in four copper nails, one by each rail on the outsode edges of the track. Solder the track to the nails, then cut through with a cutting disc (photo).